High Hopes and Tall Orders: Water towers are more than city landmarks

The duty of a water tower stretches far beyond serving as a city landmark. At the very simplest, elevated water tanks safely store treated water until it’s needed. But have you ever thought about the shape of your city’s water tower? Do you know its capacity, or what happens in an emergency like a fire, power outage or water system equipment failure?

While drinking water storage facilities – whether reservoirs, towers or tanks – are known to just silently do their job, there are several factors that go into what type of tower is right for a community. There’s no magic formula for what goes where, but there are plenty of factors to consider.

Aged tower, elevated population

Moore Engineering has helped several communities refurbish existing water towers or replace their existing tower with a higher-capacity tank when it makes sense.

The City of Finley had a water tower that had been operating for over 70 years. Props to that old beast for its longevity! But as one might expect, things changed over those seven decades, including safety standards. The new water tower, which went up in 2017, accompanied an upgraded overall water storage system. As you can imagine, the city immediately began saving on operation and maintenance costs.

In other circumstances, a city’s growth requires additional capacity. The City of West Fargo’s current population of around 35,000 is more than double what it was 30 years ago. Obviously, the city needed more water storage – if not today, very soon.

The city’s 500,000-gallon City Shop Tower had stood its ground for over 50 years. But the city was in need of additional water storage in the northwest portion of the city, and an inspection of the current water tower indicated it needed repairs. The city recently replaced it with a new 1.5-million-gallon composite water tower. West Fargo also refurbished two water towers last year (Meadow Ridge and the Twelfth Avenue tower). As if that didn’t get things flowing, the city is currently adding another million-gallon tank in its Brooks Harbor addition. These updates and additions will equip them for today and the future.

Storage types

So, how do you decide what is right for a city’s storage requirements? Operating storage, equalizing storage, fire suppression storage, contingency storage and dead storage are all considerations.

- Operating storage is the volume difference between the pump on and the pump off levels when the tank is used normally and any supply pumps are off.

- Equalizing storage is the difference between what the maximum demand might be in a day versus how much water was supplied to the system.

- Fire suppression storage is a volume of water intended for fighting fires. The typical minimum municipal fire flow requirement is 500 to 1,000 gallons per minute for two hours for residential areas, and could be up to 8,000 gallons per minute or more for large commercial or industrial areas.

- Contingency storage is used to provide water during an unusual interruption.

- Dead storage is water than can’t be drawn out because of pipe elevations for low system pressure.

All of these storage levels are calculated and considered to develop the right capacity solution for that city or area.

Shapes & Sizes

Shapes & Sizes

Water towers come in several different shapes – single-pedestal spheroids, multi-column and composite tanks are the three most common types used today. Some, like the spheroid and multi-column towers, are made entirely of steel, whereas composite tanks use more than one material, usually a concrete column shaft which elevates and supports the steel water tank above.

Why the different looks?

Aside from aesthetics, the size and type of the tower is generally determined by its function, construction and maintenance. Designers heavily evaluate a tower’s lifecycle, questioning how many times the required maintenance will be repeated. That information helps evaluate what makes the most sense for the specific application.

For instance, steel can be more expensive to maintain over its life, as these tanks generally require repainting and structural repairs every 20-25 years. Composite towers, which have a concrete support column supporting a water tank, may save costs over the long-run in that the concrete and materials used in the tower are lower maintenance.

In addition, the concrete support column provides an open space in the bottom for storage or other uses. Composite towers are often selected when there’s a need for high volume water storage. In terms of the multi-column tower versus the spheroid type – the multi-legged towers are sometimes still used and may be the most cost effective option for smaller tanks.

Some view the multi-column tanks as old-fashioned because their use began to decline in the 1960s. Now, single pedestal spheroid towers seem to be all the rage, even though they don’t offer any performance advantages. Don’t bet on the multi-column towers demise, though. Like any other style, they may become fashionable again.

Graphics

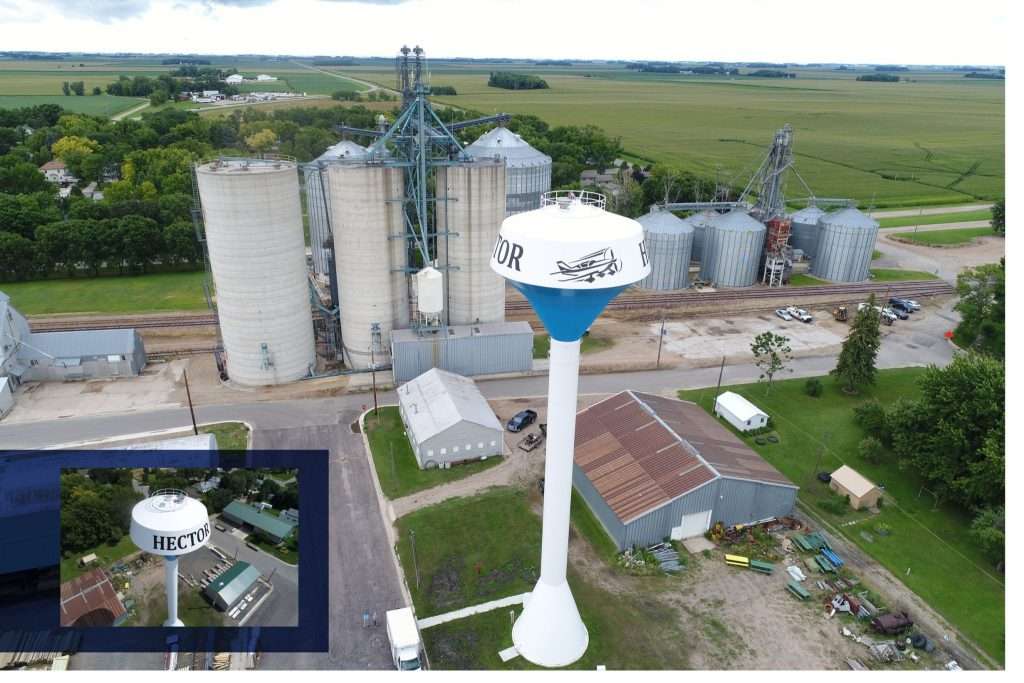

Cities are also applying graphics to their towers. In days past, the city name was generally stenciled on the side in plain lettering.

Cities are now using water towers as a promotional and artistic opportunity. Water towers are canvases to display unique community features, proclaim community or school pride and promote tourism.

Oakes, N.D., has one of the few black water towers in the state. Hector, Minn., shows off its aerial history. Finley, N.D., integrated its city logo into its water tower graphics. And Garrison, N.D.,… well, you’d have to see it to believe it!

We’re currently working on new water towers in Casselton, Kindred and New England and Turtle Lake, N.D. If you’re ready to dive in to your next water treatment or wastewater project, give us a call. We’d love to chat.